Mineral processing

Mineral processing can involve four general types of unit operation: comminution particle size reduction; sizing separation of particle sizes by screening or classification; concentration by taking advantage of physical and surface chemical properties; and dewatering solid/liquid separation In all of these processes, the most important considerations are the economics of the proceOre processing is a chain of processing applications which treats run of mine to firstly highgrade concentrate (concentration of ores) and then to the pure mineral or metal The Ore Processing Multotec

Chromium processing Extraction, Uses & Applications

Chromium processing, preparation of the ore for use in various products Chromium (Cr) is a brilliant, hard, refractory metal that melts at 1,857 °C (3,375 °F) and boils at 2,672 °C (4,842 °F) In the pure state it is 7 Sulfide Ore Refining The final step in processing sulfide ore copper from the smelter is to make high purity copper cathodes 8 Copper Products & Many Uses Copper cathodes From Ore to Finished Product Copper

Lithium Production Processes ScienceDirect

The production of lithium has increased rapidly over recent years due to its high demand in the manufacture of lithiumion batteries (LiBs) used for portable Ore, a natural aggregation of one or more minerals that can be mined, processed, and sold at a profit An older definition restricted usage of the word ore to metallic mineral deposits, but the term has Ore Processing, Extraction & Refining Britannica

Iron processing Ores, Smelting, Refining Britannica

Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together For this purpose, a travelinggrate machine is used, This review focussed on two main aspects of oolitic iron ore processing: beneficiation by conventional mineral processing techniques (differential grinding, scrubbing, gravity Iron Ore Processing an overview ScienceDirect Topics

Nuclear fuel cycle' Extractingg uranium from its ores

The runofmine ore, which in some instances may be 25cm or more in diameter, is crushed and then ground to the consistency of fine sand Since most ores being processed today contain from about 002% to 02% recoverable uranium, it is necessary to process from 500 to 5000 kg ore for each kilogram of uranium recoveredaluminum processing, preparation of the ore for use in various products Aluminum, or aluminium (Al), is a silvery white metal with a melting point of 660 °C (1,220 °F) and a density of 27 grams per cubic cm The most Aluminum processing History, Mining, Refining,

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushing This step prevents overloading the crusher and increases its efficiencyOrder management refers to the process of receiving, tracking, and fulfilling customer orders The order management process begins when an order is placed, and ends when the customer receives their package When scaling your business, it’s important to automate and streamline this process — otherwise, you’ll eventually be What is Order Management? Processing, Fulfillment, and More

Iron ore facts and common questions answered FocusEconomics

In addition to steel prices, the health of China’s economy is strongly linked to iron ore prices As China’s economy has slowed in recent years, so has demand for iron ore and prices have consequently fallen Iron ore prices averaged over USD 130 per metric ton in 2013 Last year they averaged just over USD 58 per metric tonCopper Processing Copper processing uses physical, mechanical and / or chemical methods to convert runofmine (ROM) copper ore to highquality, pure copper A wide range of mineral processing equipment is used in converting the copper ore to the final copper product, our solutions range includes: Screening Solutions Cyclone SolutionsCopper Processing Multotec

Payments 101: How Online Payment Processing Works Rapyd

Customer selects payment method at checkout It’s encrypted via a payment gateway and sent to the payment processor The sale is authorized The transaction is approved by the customer’s card issuer, bank or digital wallet Funds are sent to the merchant bank, less the payment processing feesIron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic Iron Ore Processing, General SpringerLink

Copper processing Ores, Refining, Smelting Britannica

Principal forms in which copper ores are found include native copper, porphyry copper, massive deposits, and mixed ores Native copper is simply the metal found unadulterated in nature Occasionally copper is still found in its native form, but more frequently it is mixed with other minerals, some of which may have value themselves The amount of copper in Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together For this purpose, a travelinggrate machine is used, and the burning of fine coke (known as coke breeze) within the ore generates the necessary heat Before being delivered to the sinter machine, the ore mixture isIron processing Ores, Smelting, Refining Britannica

Copper Mining and Processing: Processing Copper

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday Ore is a deposit in Earth’s crust of one or m ore valuable minerals The most valuable ore deposits contain metals crucial to industry and trade, like copper,gold, and iron Copper ore is mined for a variety of industrial uses Copper, an excellent conductor of electricity, is used as electrical wire Copper is also used in constructionOre National Geographic Society

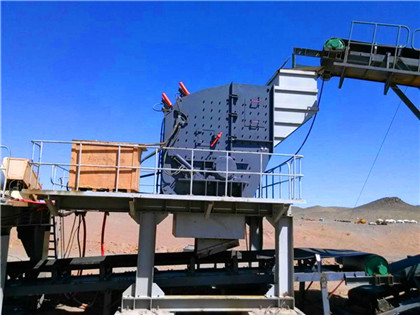

Mineral processing

Crushing, a form of comminution, one of the unit operations of mineral processing In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable minerals from their ores [1] Gold Mining Operation: 10 30 years The gold mining operation stage represents the productive life of a gold mine, during which ore is extracted and processed into gold Processing gold involves transforming rock and ore into a metallic alloy of substantial purity known as doré typically containing between 6090% goldHow Gold Is Mined Gold Mining Process World Gold Council

A brief introduction to production of titanium dioxide and titanium

Titanium dioxide is used as pigment material in the production of paints, paper, and many other products as well as a precursor material that is subsequently processed to produce titanium metal Titanium tetrachloride is used as a precursor to titanium metal production via the Kroll process The titanium is first processed at the ore Although there are over 145 minerals that contain lithium, only five are used for commercial lithium extraction: spodumene, lepidolite, petalite, amblygonite, and eucryptite Of these, spodumene is the most abundant, yielding the vast majority of mineralderived lithium Australia accounts for much of the world’s spodumene production, withLithium Extraction STT Systems and Solutions

Copper Production: How Is Copper Made? ThoughtCo

If economical, lesser impurities that may be present in the ore, such as molybdenum, lead, gold, and silver, can also be processed and removed at this time through selective flotation At temperatures between 9321292 ° F (500700 ° C), much of the sulfur content remaining is burned off as sulfide gas, resulting in a calcine mix of In this study, a novel intelligent factorywide operation system for a continuous production process is designed to optimise the entire production process, which consists of multiple unitsFlow chart of the mineral processing of hematite iron ore

What is Data Processing? Definition and Stages Talend

Processing is done using machine learning algorithms, though the process itself may vary slightly depending on the source of data being processed (data lakes, social networks, connected devices etc) and its intended use (examining advertising patterns, medical diagnosis from connected devices, determining customer needs, etc) 5Ore is a deposit in Earth’s crust of one or m ore valuable minerals The most valuable ore deposits contain metals crucial to industry and trade, like copper,gold, and iron Copper ore is mined for a variety of industrial uses Copper, an excellent conductor of electricity, is used as electrical wire Copper is also used in constructionOre Education National Geographic Society