(PDF) MECHANICAL COMPORTEMENT OF A CEMENT

In this work we study the mechanical behavior of a rotary kiln of the LAFARGE OGGAZ cement plant, we took the case of a laser equipment to capture data with a high degree of accuracy, calculating the position of the kiln shell rotational axis at each support Calculations include allowance for flexure, Rotary Kiln Maintenance Get the most out of your equipment

Rotary kiln process: An overview of physical mechanisms, models

Slightly inclined (~3°), the kiln can reach 80 m in length and 6 m in diameter, while its rotation is relatively slow (from 2 to 10 rpm) Despite several A rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process Materials produced using rotary kilns include: Cement; Lime; Refractories; Rotary kiln

Full article: Modeling operational cement rotary kiln variables with

Formulae display:? Digitalizing cement production plants to improve operation parameters’ control might reduce energy consumption and increase process Establishment of the 3D model of the rotary kiln is mainly to define each component’s structure and material properties Without affecting the study results, Advances in Mechanical Engineering 2015, Vol 7(6) 1–15

Failure Analysis of Refractories in Rotary Kilns SpringerLink

To study the destruction of lining refractories, a calculation method has been developed that makes it possible to analyze the formation of destruction (splitting) The present paper aims to establish a basis for developing a tool for coupled thermalmechanical analysis of a rotary kiln, applicable to similar devices to Transient operation effects on the thermal and mechanical

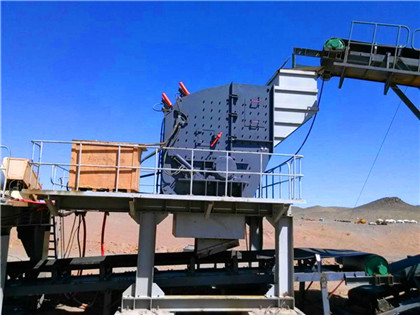

Key Factors in Rotary Kiln Shell Design AGICO

The length of each part of a rotary kiln is designed based on the inner diameter (D) of the kiln shell 1) The length of the kiln head overhanging section (l1): l1= (12~15) D As the first section of a rotary kiln, l 1 is Most of the unplanned shutdowns for refractory maintenance, in cement plants, are due to the refractory problem in rotary kiln It is to be borne in mind that Rotary kiln is huge in size and mass and is not stationary but dynamic in nature, which has made it very special from other static furnaces A kiln of 6 m diameter and 60 m length, forRefractory Design, Installation, and Maintenance SpringerLink

Analysis of the Loads Acting on Rotary Kiln & Hydraulic Design

As a result of the calculation, it was concluded that the pinion gear is exposed to 21,208 kN and the torque value is 6097,3 Nmm By system at rotary kiln Generally, mechanical driven rotary kiln system is preferred Because, hydraulic requires expertise compared to other systems High capacity forces can be obtained by using hydraulicdesigning rotary kiln The ROTARY KILN HANDBOOK OPERATION SIZING & DESIGN CONSIDERATIONS MAINTENANCE a product of Contents INTRO About FEECO 1 Intro to Rotary Kilns 3 ROTARY KILN OPERATION & PROCESSING How Rotary Kilns Work 5 Rotary Kiln Processes 8 SIZING & DESIGN Rotary Kiln Sizing & Design 11 Increasing (PDF) Rotary Kiln Handbook NEW Ahmad Reza Jamali

Rotary Kiln, a Unit on the Border of the Process and Energy

complex solutions consider both the operational (mass calculations) and the energy aspects (energy calculations) of the integration as a basis for the energy sustainability and low environmental impact of rotary kilns within industrial processes Keywords: rotary kiln; cement kiln; waste; alternative fuel; combustion; artificial A number of samples from the preburning zone of a wetprocess cement rotary kiln were examined by combined DTA/TG and XRD for estimation of spurrite (2Ca2SiO4CaCO3)Calculation of the formation process of clinker inside the rotary

Rotary Kiln IspatGuru

The kiln is set at a slight angle, in order to allow gravity to assist in moving material through the rotating cylinder Rotary kiln can be either of the directfired type, or the indirectfired type In a directfired kiln, a fuel is burnt in the drum, and the material is processed through direct contact with the flue gasProcess parameters of both pyrolysis techniques are displayed in Table 1 A rotary kiln operating at 10 rpm maximized homogeneous heat transfer and mixing of the solids [21] at a conventionalIndustrial Applications of Rotary Kiln in Various SectorsA Review

Hazardous waste incineration in a rotary kiln: a review

Hazardous waste output in the world is increasing every year To achieve higher efficiency and lower pollution, the incineration technology for hazardous waste needs to be studied further This study mainly reviews the research progress in incineration, slagging, and pollutant emission in the rotary kiln in China and abroad in Immediately after preheating, it enters the rotary kiln of 22 m in diameter and 158 m in length with a rotational rate of 6 rpm The solid mixture of leached sand and stuffing ions is then(PDF) Design of Rotary Kiln for Cristobalite Production

Rotary cement kiln calculations, kiln residence time, Burning

L/D Effective DiaDeff, m Effective CS Area, m 2: Effective Kiln Vol m 3: Rad Surface Area, m2 Potential Capacity tpd Degree of filling DF%The rotary kiln furnace represents an intermediate stage in FeNi production via the Rotary KilnElectric Furnace (RKEF) process, as shown in Fig 1In this stage, fresh minerals enter the kiln with reductant coal, and the resulting mixture undergoes a series of physical and chemical transformations, producing calcined minerals, also known as calcineTransient operation effects on the thermal and mechanical

Analytical and Numerical Stress Analysis of The

The rotary cement kiln forms a major part of any cement works The kiln is a large cylindrical structure where the raw materials are brought together and heated to form clinker, the base materialA rotary kiln is a unique facility with widespread applications not only in the process industry, such as buildingmaterial production, but also in the energy sector There is a lack of a more comprehensive review of this facility and its perspectives in the literature This paper gives a semisystematic review of current research Main trends Rotary Kiln, a Unit on the Border of the Process and Energy

Cement Kilns: Design features of rotary kilns

Mechanical Considerations All rotary kilns essentially take the form of beams supported at a few points the tyres (riding rings) along their length, with the added complication that they rotate The shell has to cope with all the forces involved, but is necessarily thin, since weight must be minimisedRaw materials that are hard with mechanical strength of 20 –30MPa are better burnt rotary kiln combination is a synergy of the shaft and rotary kiln technologies It will allow for wider utilization of available sometimes The calculation is based on heat required to or lost during the production of 1kg CaO of limeTHE DESIGN OF ROTARY KILN WITH CYCLONIC HEAT

Full article: Modeling operational cement rotary kiln variables

The preheater and rotary kiln key operating parameters are summarized in Table 1 Variables were monitored hourly and were taken into account In general, over 3,000 records from 2020 to 2021 were prepared and used for the modeling In the plant, before the introduction in the rotary kiln, the raw meal is preheated through a A rotary kiln is a unique facility with widespread applications not only in the process industry, such as buildingmaterial production, but also in the energy sector There is a lack of a more comprehensive review of this facility and its perspectives in the literature This paper gives a semisystematic review of current research Main trends Sustainability Free FullText Rotary Kiln, a Unit on the Border of

Kiln training PPT SlideShare

Mechanical maintenanceofcementrotarykiln mkpq pasha Page 5 Rotary kiln assembly 1 Rotary kiln shell 7 Guard for rack and pinion drive 2 Kiln inlet with inlet seal with lubrication device 3 Tires with fastening 8 Kiln drive system 9 Kiln Page 22 Description of the kiln shell calculation basics The shell is a rotating drumProcess description The rotary kiln, for which the implementation of the examined recuperator is proposed, is schematically shown in Fig 1 The kiln is 80 m long, with the outer diameter of 28 m, rotates with the speed of 075–095 rpm, and is a part of a magnesium production processRecuperator for waste heat recovery from rotary kilns